RR Racing Brake Systems

Our brake kits are engineered from the best-in-class components, carefully designed, selected, and/or manufactured by us right here in the United States to the highest quality standards. Our goal is to meet and exceed all quality, performance, aesthetic characteristics of top brands such as Brembo and AP Racing at an affordable price. All of our braking systems are track tested in very demanding conditions (please refer to our News page for latest track testing articles).

Big Brake System Components:

Competition Rotors

The central part of our competition big brake kit systems is our high end competition two piece floating rotor.

We start with discs from Coleman Racing, utilizing the same exact materials, metallurgy, and design as featured on top NASCAR Winston Cup and professional road racing. These extra heavy duty high carbon steel discs have directionally curved cooling vanes which actively pump air to cool the rotor. These discs combine unparalleled strength and durability to satisfy the most demanding competition requirements for both street and track use. We then zinc chromate plate the discs for superior corrosion resistance and durability. We offer both slotted and drilled patterns. Coleman Racing discs are balanced to high tolerance, which reduces feedback associated with rotor vibration and provides a smooth confident application of braking force.

The two piece floating design is used in the most advanced applications to accommodate for thermal expansion under the most demanding track conditions. The two piece design also allows reducing the weight of the rotor by utilizing billet grade aluminum alloy for the hat.

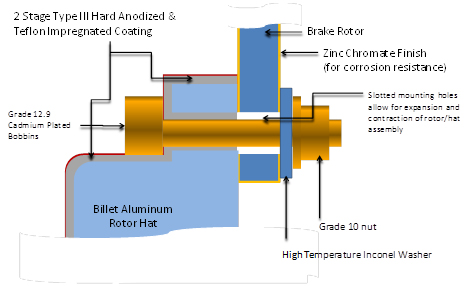

The following diagram illustrates our two-piece floating design.

The hats are made by us in United States with US sourced material to the most demanding quality specifications. High strength billet aluminum is utilized for both strength and lightness. We hard anodize our hats to increase hardness and corrosion resistance. In addition to the hard anodized surface treatment, we take it a step further with Teflon Impregnation for superior aesthetic and durability as shown in the diagram below.

2 Stage Type III Hard Anodized & Teflon Impregnated Coating

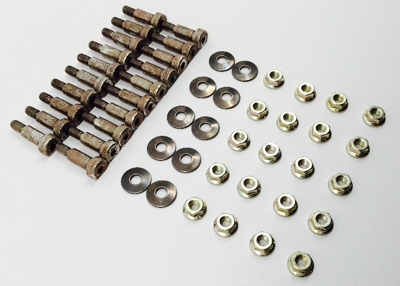

High grade 10-12.9 mounting hardware is used. Our bobbin fasteners are Cadmium plated for superior corrosion resistance.

Calipers

After testing a variety of calipers for our high end brake kits, we concluded that Wilwood calipers offer the best performance at a great value. RR Racing Wilwood calipers were carefully selected and extensively tested with our braking systems. We utilize several four and six piston calipers with varying sizes ranging from FNSL6R in our Stage I kit and FSL6R in our high end and Competition kits. We also use Aero6 for our large disc Competition kits (e.g., ISX competition brake kit).

The Wilwood Forged Superlight 6R series is the benchmark in street and track applications. It also enjoys prominence in a variety of road-race, rally and sport driving. The new FSL6R model series is the latest innovation to this Superlite family of calipers. It has been redesigned with internal fluid ports that eliminate the external fluid cross-over tubes. The transfer tube has been replaced with two additional bleed screw assemblies which allow differential bore models to have a left hand and right hand orientation, but no leading or trailing configuration is required.

The Forged Narrow Superlite 6R (FNSL6R) is Wilwood’s newest version for the venerable Superlite caliper series adds the versatility and convenience of radial mounting to this widely popular caliper group. Radial mounting simplifies adaptation and provides two planes of adjustment for accurate alignment over the disc. These calipers integrate "Big Brake" style with Wilwood's latest technology to generate big stopping power in extreme environments over a broad range of vehicle applications.

The new Aero6 forged six piston caliper delivers heavy duty stopping power for the road or track. The caliper incorporates race technology into a body design with widespread adaptability. Radial mounting, multiple options for piston volume, and large rotor diameter (we use it in our 14 inch kits) give this caliper the versatility necessary to suit all types of heavy weight braking requirements.

In most of our kits we offer Wilwood calipers in black or red powder coated colors. Wilwood calipers offer both superior performance and great aesthetic looks. Our competition kits feature black anodized calipers to withstand the extreme temperature conditions associated with track use.

Update September 2015: We now offer the calipers on variety of standard colors and any custom colors that could be selected from www.g2usa.com. Calipers are painted using a two component high temperature paint. We found this paint very durable even after repeated track uses (although we recommend the anodized version for heavy track/racing applications). Painted calipers get a great looking RR Racing logo, or our customers can specify no logo for applying their favorite car logo (as shown on the GS350 application photo below).

Offering custom calipers colors is a unique feature in the market today, and we feel it provides an important service to our customers looking for a unique look. We engineer our brake systems for best quality, variety of flexible options at a great price!

Brake Pads

We offer Wilwoods BP10 through BP30 pads as well as Hawk HP-Plus pads as an option for some of our high-end braking systems. Temperature range and overall friction value are the primary considerations for pad selection. The pads must be capable of maintaining the proper amount of friction for stopping power within the temperatures that will be realized during demanding road applications or on the track. Then, overall wear rate must be considered. For most asphalt and road race applications, compounds in the high temperature ranges over 1000°F range are usually necessary. Dirt track, drag race, and street performance applications usually operate at temperatures between 500° and 1000°F. The best indicator for pad selection will always be on track performance – this is why we test our brake systems on the track.

We also like the Winmax brake pads. Winmax offers a variety of pad options starting at high performance street use through tracking and racing. We like Winmax pads for their temperature and friction characteristics. We feel they fit well with certain OEM and RR Racing brake systems.

Please refer to our Pad Guide for more technical information about our brake pad options: Brake Pad Selection Guide

Titanium Shims

For selected racing applications we offer our own designed and manufactured Titanium Pad Shims. In race applications, it is common to use titanium backing plates to reduce heat transfer between the brake pad to the caliper pistons. Titanium is superior to common steel backing plates due to its lower thermal conductivity. It acts as an insulator to prevent heat transfer to the caliper pistons and brake fluid.

Brake Lines

We exclusively use Goodridge USA stainless steel brake lines. High speed heavy braking puts great strains on competition hydraulic systems, where failure can be disastrous. Goodridge stainless steel hose strongly resists expansion under high pressure and temperature, provides consistent brake pedal pressure giving firmer and more efficient operation without that spongy feeling. These brake line systems offer protection against abrasion and fire. Its microbore construction can give increased line pressure and more responsive and sensitive brake feel.

Mounting Brackets

RR racing designs and manufactures caliper mounting brackets needed for each of our big brake kits. Mounting brackets are made of high strength aircraft aluminum for both durability and light weight. We machine our brackets using the latest CNC milling machines to high quality standards right here in United States. As with all our aluminum components, we black anodize our brackets to give them superior strength and corrosion resistance.

For more information about our brake systems products, please visit our on-line catalog for your model.